Michael Abt, M. Sc.

- group: Bioengineering and Biosystems

- room: 101

CS 30.43 - phone: +49 721 608-42125

- michael abt ∂does-not-exist.kit edu

Research

Research topic:

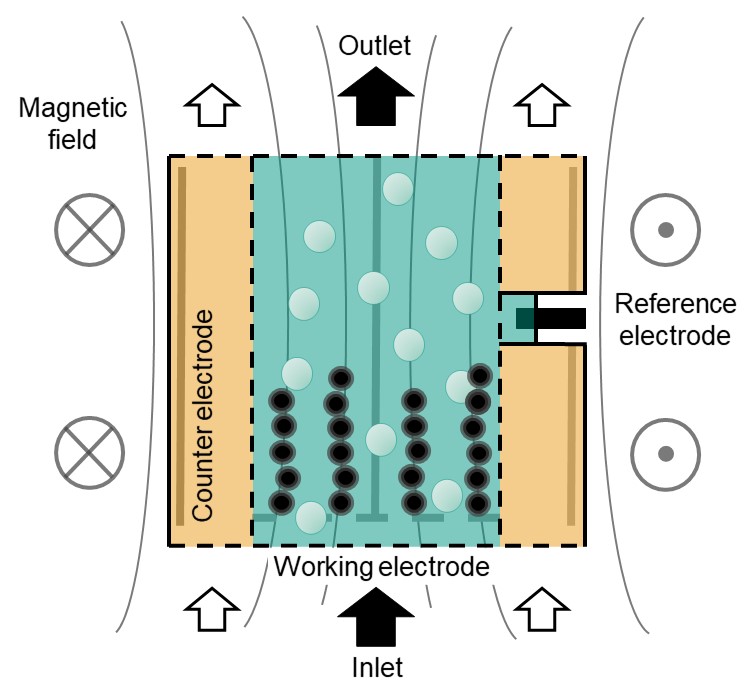

Magnetically enhanced electrochemical fluidized bed reactors for electro-enzymatic syntheses including gaseous phase

Description:

Traditional processes for chemical synthesis use fossil resources and cause emissions detrimental to the climate. An innovative and green alternative presents electro-biosynthesis that combines electrochemistry with biotechnology. The concept of electro-biosynthesis is to use electricity generated by renewable energy, green catalysts (e.g. enzymes) and renewable resources in order to produce chemicals “carbon neutral”. To achieve competitive electro-biosyntheses, we aim to reach high space-time yields which require electro-bio reactors with high volume specific electrode surfaces.

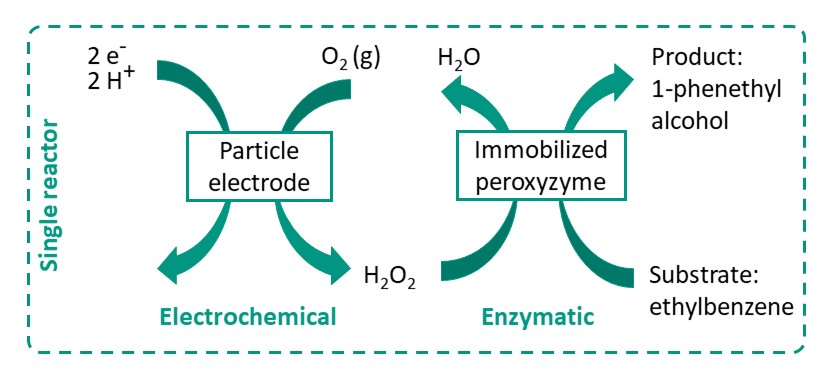

The efficiency of the novel reactor concept for electro-enzymatic synthesis will be demonstrated by the in-situ generation of hydrogen peroxide which is required for oxyfunctionalisation reactions using peroxygenases (see figure 2). The whole project will be accompanied by a close feedback between experimental results and multiphysics modelling approaches. The reactor prototypes will be produced via 3D printing technology.

Theses:

We assign Bachelor’s and Master’s theses. Possible tasks can be experimental or a simulation. Depending on your interests we can put more emphasis on biotechnology, on process engineering or on electrochemistry. Feel free to contact me via e-mail (see above).

Figure 1: Schematic illustration of a magnetically stabilized fluidized bed electrode operated with

three phases: magnetizable particle electrode (black particles), liquid phase (green/yellow) and gas phase (grey bubbles).

Figure 2: Simplified reaction schema of the electro-enzymatic model reaction. In the reactor we generate hydrogen peroxide in-situ (on demand) via a particle electrode. The enzyme, a peroxygenase, uses hydrogen peroxide as co-factor for the oxyfunctionalization of ethylbenzene to 1-phenethyl alcohol.