M.Sc. Robin Wagner

- phD-student

- group: Bioengineering and Biosystems

- room: 238

- phone: +49 721-608-22986

- robin wagner ∂does-not-exist.kit edu

Research

Multi-scale simulation of electrochemical processes and apparatus with regard to applications in biotechnology

The purification of biotechnological synthesized molecules is an elaborate part of the manufacturing process, which is often realized by means of chromatography. An interesting alternative to chemically controlled chromatography methods, e.g. Ion Exchange Chromatography or Hydrophobic Interaction Chromatography is the physical stimulus controlled Potential-Controlled Chromatography (PCC). PCC is also suitable for the purification of ions or charged molecules such as amino acids, which are used, for example, as food additives or as feedstuffs.

As the PCC is still under development, the understanding of the processes taking place on nano-, micro- and macroscale is only partially existent. However, this knowledge is crucial for the optimization and design of this technique.

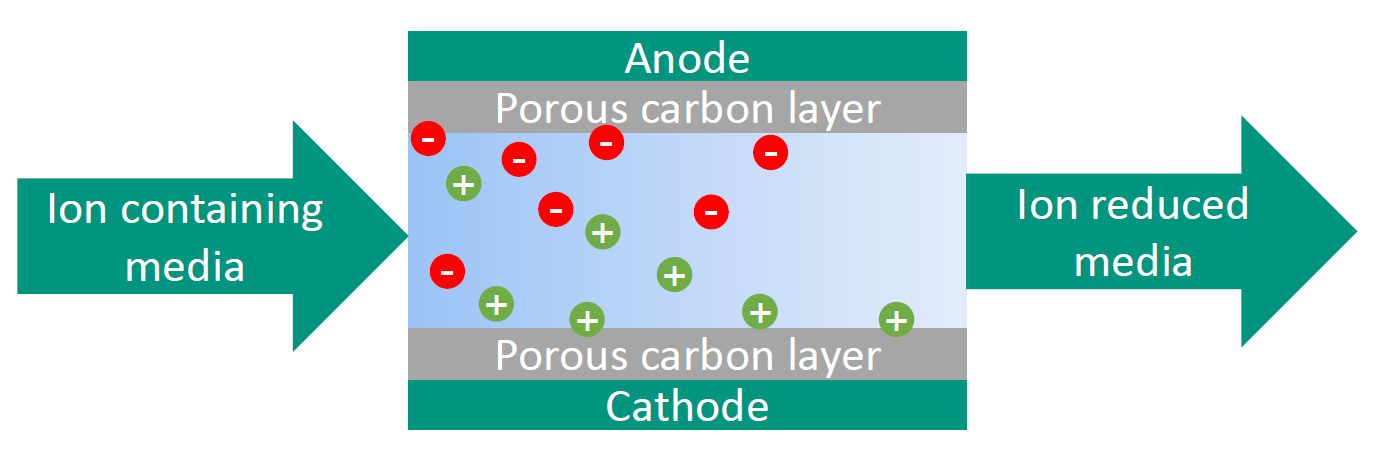

In order to gain a better understanding, the expiring processes are simulated in a multiscale model and experimentally investigated. For the modeling, the adsorption and diffusion processes in the porous carbon layer of the flat electrodes, as well as the convective transport processes and the electrotechnical behavior of complete electrode modules are included. The experiments are performed on an with a PCC module extended FPLC-plant, whereby the adsorptive forces are induced by cyclic voltage and power sequences. The test substances are amino acids, salts, acids and alkalis.

The objective of this project is the creation of a realistic predictive simulation program for electrochemical processes with capacitive flat electrodes.

Figure 1: Working principle of a PCC-module. Positively charged ions/molecules are adsorbed at the anode, while negatively charged ins/molecules are adsorbed at the cathode. After passing the CDI-module the media has a smaller proportion of ions/molecules.