Functionalized coatings

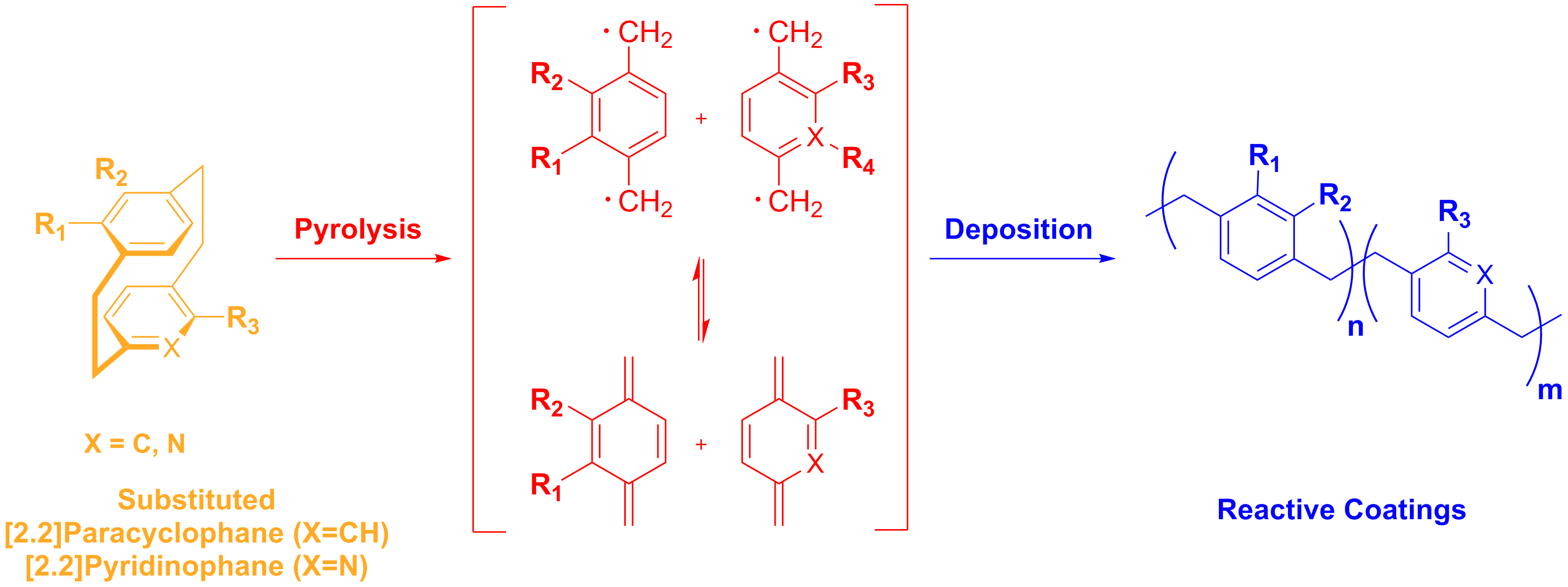

Chemical Vapor Deposition Polymerisation of functionalized [2.2]paracyclophanes

Many reactions in biology and/or catalysis take place at interfaces, which are defined by specific functional groups on the surface. Therefore, surface modification of complex substrates is a key challenge to the development of novel reactive coatings. Chemical Vapor Deposition (CVD) polymerization is a versatile process to produce reactive polymer coatings on a broad range of materials with various geometries (2D/3D substrates).

Using a wide class of substituted [2.2]paracyclophanes, our custom-built CVD system enables the fabrication of functionalized poly(para-xylylene) coatings made of homopolymer, copolymers, and copolymer gradients. Comprehensive characterization of these coatings is performed using analytical equipment (e.g. IRRAS, Spectroscopic Ellipsometry, AFM).

Applying orthogonal coupling techniques, these coatings can be utilized for the immobilization of biomolecules or other molecules of interest for applications in (bio)sensor technologies, catalytic devices or tissue engineering.

Surface modification via controlled radical polymerization

Atom Transfer Radical Polymerization (ATRP) and Reversible Addition-Fragmentation chain-Transfer Radical polymerization (RAFT) are Controlled Radical Polymerization techniques to prepare materials with controlled topology or composition. Such materials are suited for biomedical applications and basic stem cell research. Using these techniques, novel zwitterionic polymers can be synthesized as stem cell culture substrates that are synthetic and fully defined in a reproducible manner. These polymers can also be used to fabricate scaffolds with increased complexity to control the cellular microenvironment.

Micro- and nanostructured surfaces

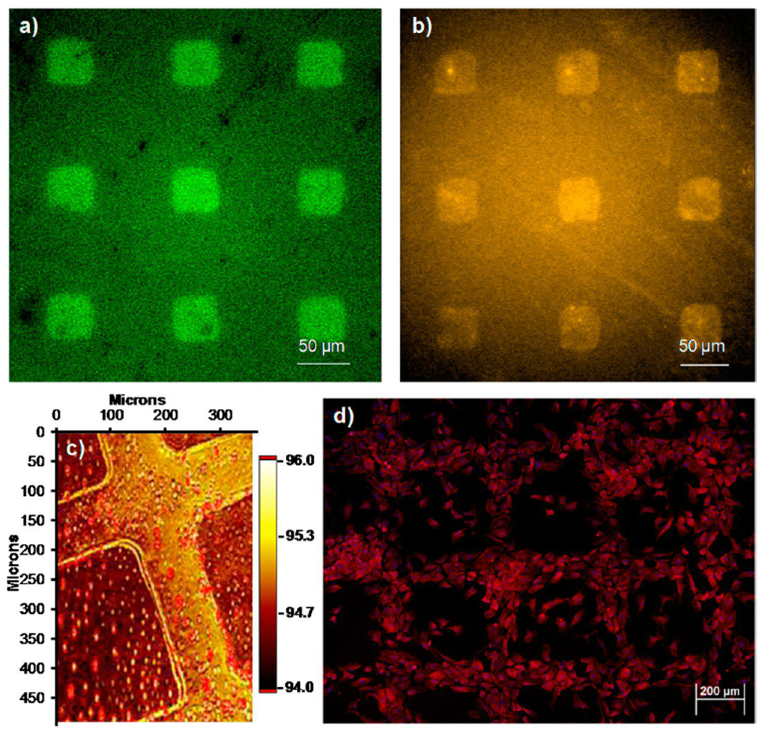

Micro- and nanostructured substrates can be engineered through the use of different patterning techniques, which may be combined with orthogonal immobilization strategies such as click reactions to produce complex structures for various applications.

Patterning on functional surfaces can be accomplished using techniques such as microcontact printing, photopatterning, or lithographic techniques such as Dip-Pen Nanolithography.

Structured CVD coatings can be produced during the deposition process by the so-called VAMPIR-Process (vapor-assisted micropatterning in replica structures).

Electrohydrodynamic Co-Jetting

Electrohydrodynamic co-jetting is a process developed for manufacturing multi-compartmental fibres, nano- or microparticles. We produce a large range of sizes and shapes. The use of orthogonally, functionalized polymers enables the selective, subsequent modification of the compartments.